bohlerstrip

NFM Special Strip

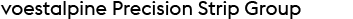

Laser welded multi-material strip products for applications in the electronic and automotive industry in the field of non-ferrous-metals - welded strip products made in copper, in the longitude combination with copper alloys or steel for new possibilities for stamped and stamped/bent components.

CONNECTORS

WITH

PARTICULAR

PROPERTIES

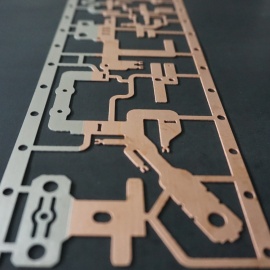

Utilise the advantages of steel. By combining the materials copper or a copper alloy with steel we can provide structural components with the opportunity to integrate the advantages of steel or to „design them in“. Certain steels have a considerably higher degree of hardness or elasticity compared to copper, and these can be used above all in the fields of electrical plug-in connections or spring contacts. Over and above this, combining with a corrosion-resistant or acid-resistant steel into a welded strip makes uses in more demanding environments possible, such as for example in the field of automotive fuels.

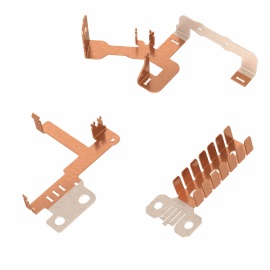

Our special strips can be manufactured with an even thickness throughout or also with a welded step. Both flat, even strips as well as stepped strips are over-rolled, so the weld seam is levelled off and flattened down. A higher degree of re-forming and shaping is possible with a relatively constant hardness of components. By so doing, the weld seam disappears entirely from view and often can only still be detected during the colouring process. Further surface treatments such as brushing, polishing or passivating are likewise possible.

APPLICATION FIELDS

» Automotive

» Power erlectronics

» Power train

» Electrical supply

» Aerospace

» Welding processes

Our special strips can be manufactured with an even thickness throughout or also with a welded step. Both flat, even strips as well as stepped strips are over-rolled, so the weld seam is levelled off and flattened down. A higher degree of re-forming and shaping is possible with a relatively constant hardness of components. By so doing, the weld seam disappears entirely from view and often can only still be detected during the colouring process. Further surface treatments such as brushing, polishing or passivating are likewise possible.

APPLICATION FIELDS

» Automotive

» Power erlectronics

» Power train

» Electrical supply

» Aerospace

» Welding processes

| SPECIFICATION | |

| Strip thickness flat | 0,40 mm to 2,00 mm |

| Strip thickness with step | one component up to 4,00 mm |

| Strip width | up to 120,00 mm welded strip |

| Welding seam | rolled, flat |

| Optional surface | brushed, slightly oiled or passivated |