bohlerstrip

NFM Special Strip

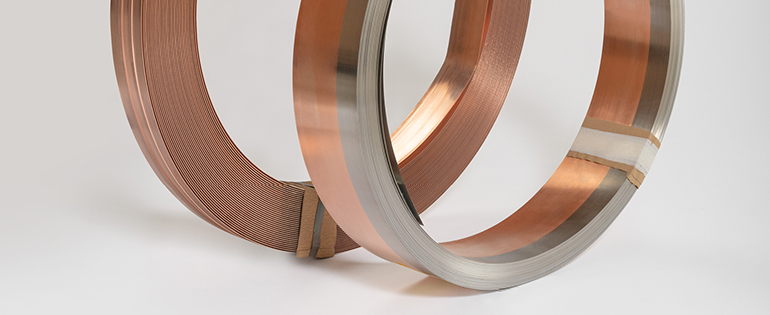

Laser welded multi-material strip products for applications in the electronic and automotive industry in the field of non-ferrous-metals - welded strip products made in copper, in the longitude combination with copper alloys or steel for new possibilities for stamped and stamped/bent components.

Aluminium-Copper-Compound

The copper-aluminium connection for various applications in the electronics sector, manufactured using a combination of two proven processes: Roll cladding and laser welding. This brings two decisive advantages.

Battery technology is one of the fastest growing industrial sectors. And if you work in this field, sooner or later you will come across the necessary transition from aluminium to copper - whenever battery cells need to be connected to each other or measurement technology needs to be integrated.

Unlike steel-to-copper or copper-to-copper connections, conventional connection technologies cannot be used without restrictions. In the cladding process, hardness limits are reached relatively quickly. In the welding process, it is intermetallic phases that act as obstacles to the flow of current. We have developed a process that overcomes both technical limitations.

POSSIBLE APPLICATIONS

» Battery connector or battery measuring tap in the field of electromobility

» Thick wire bond surface for electronic components without AlSi coating

» Aluminium cables or cable lugs in the field of electromobility

ADVANTAGES

» High-quality and durable bonding of copper and aluminium in one strip

» Bonding especially with harder copper alloys,

such as CuSn6 or CuNiSi - defined hardness

» Small quantities for sampling from 50 kg possible

Battery technology is one of the fastest growing industrial sectors. And if you work in this field, sooner or later you will come across the necessary transition from aluminium to copper - whenever battery cells need to be connected to each other or measurement technology needs to be integrated.

Unlike steel-to-copper or copper-to-copper connections, conventional connection technologies cannot be used without restrictions. In the cladding process, hardness limits are reached relatively quickly. In the welding process, it is intermetallic phases that act as obstacles to the flow of current. We have developed a process that overcomes both technical limitations.

POSSIBLE APPLICATIONS

» Battery connector or battery measuring tap in the field of electromobility

» Thick wire bond surface for electronic components without AlSi coating

» Aluminium cables or cable lugs in the field of electromobility

ADVANTAGES

» High-quality and durable bonding of copper and aluminium in one strip

» Bonding especially with harder copper alloys,

such as CuSn6 or CuNiSi - defined hardness

» Small quantities for sampling from 50 kg possible

| Properties | |

| Thickness aluminium | 0.60 mm to 1.80 mm |

| Thickness copper | 0.35 mm to 1.80 mm |

| Width of welded strip | up to 120.00 mm |

| 1. component material | Al99,5 with Cu OF edge platted |

| 2. component material | Cu-HCP, CuNiSi, CuSn6, CuNi3SiMg, CuCrSiTi |

Aluminium-copper composite material - roll-clad and laser-welded. Used in various OEM series of German premium car manufacturers.

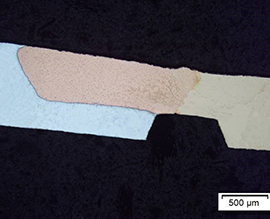

Micrograph of the joint